Long life and high quality are distinctive features of ASK products. We achieve this through production control in conformity to DIN ISO 9001, combined with the latest techniques and our high proportion of in-house manufacturing.

In addition to quality, our customers expect a broad degree of variability, associated with quick availability of all products. Automated production allows us to manufacture more than 6000 production and custom versions.

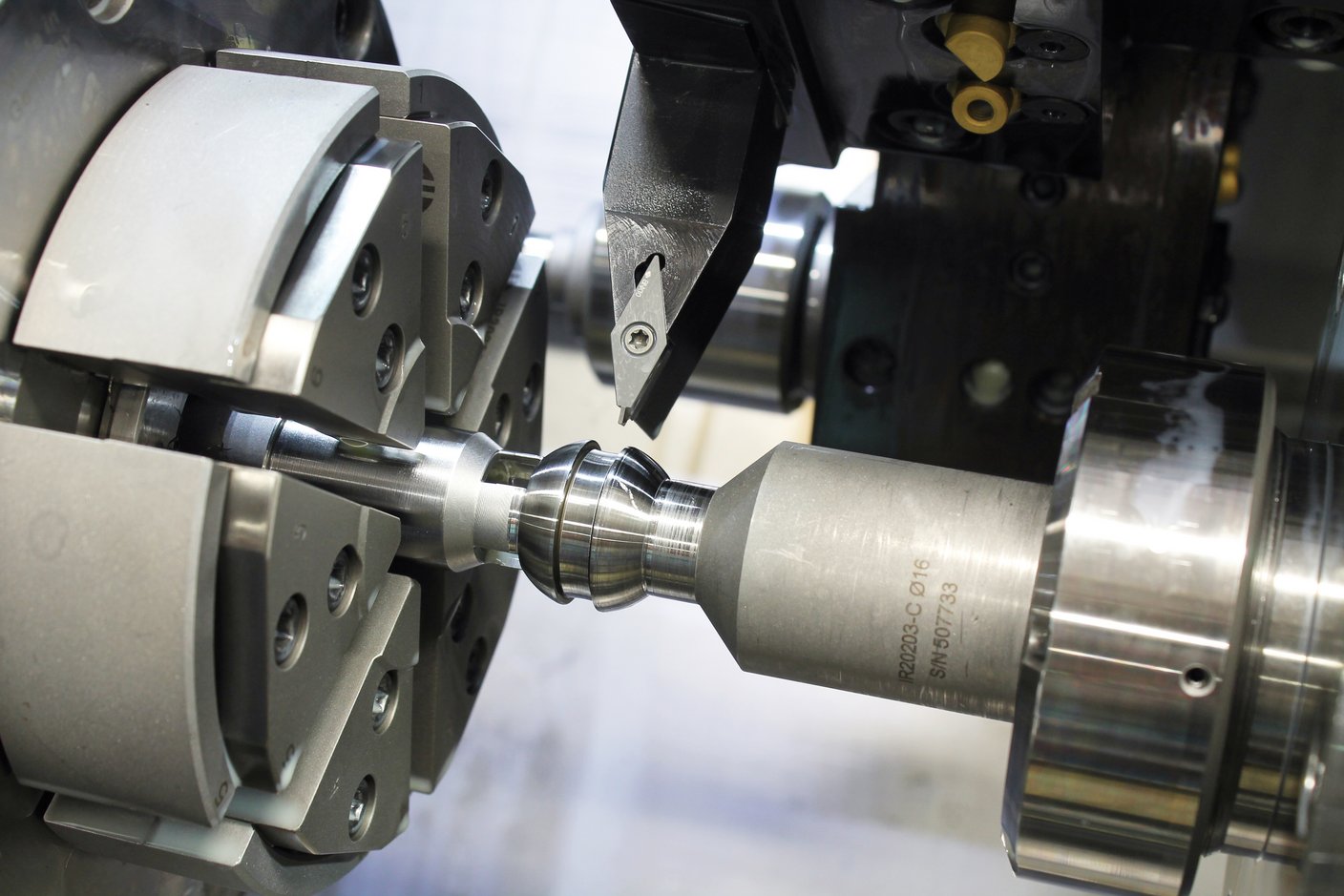

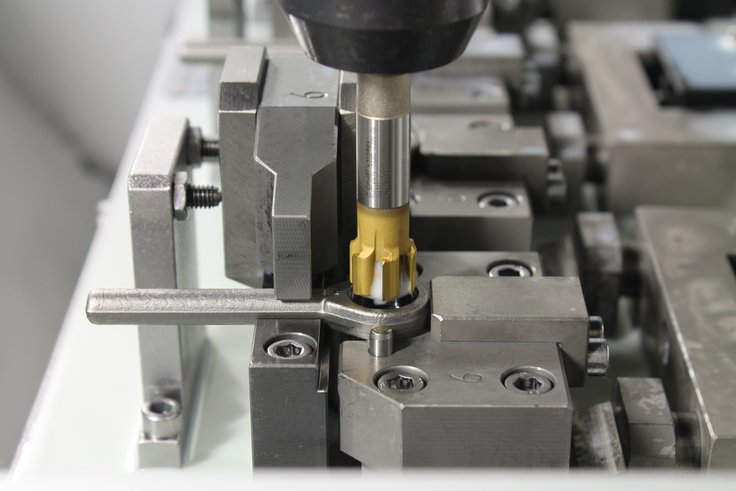

The output from our three production lines exceeds 6000 production and custom components. Our forged components are further processed by machining and reshaping. The smaller sizes are manufactured in our pre-production from solid materials. Then the semi-finished products move on to the assembly machines.

To respond to the constantly rising expectations of our customers, we are relying increasingly on high-performance materials for our tools and production.

The results are short retooling times and digital monitoring of our production systems. This maximizes our flexibility.

Concern for the environment is a top priority at ASKUBAL. We manufacture in ways which conserve the environment and we are constantly guided by current and future standards. Our machine tools operate on the principle of minimal lubrication quantities, without having to compromise on the service life of our tools.

- ON THREE PRODUCTION LINES

- CUSTOMISED

- WITH SHORT RETOOLING TIMES AND MAXIMUM FLEXIBILITY

- USING NEW TECHNOLOGY TO MAXIMIZE PERSONAL AND ENVIRONMENTAL SAFET